Views: 0 Author: Site Editor Publish Time: 2025-08-22 Origin: Site

When you ask, "how is milk made" on a modern milk production line, you find three main stages: milking & collection, processing, and packaging/distribution. Each stage in the production process keeps milk safe and high quality. You see strict hygiene and animal care during collection. Processing steps like pasteurization remove harmful bacteria. Packaging and distribution keep milk fresh for you. The production process supports over 600 million people worldwide, with 782 million tonnes of milk produced in 2023.

Statistic |

Value |

|---|---|

Total milk production in 2023 |

782 million tonnes |

Cow's milk share of total |

81.1% |

People supported by dairy farms |

Over 600 million |

You benefit from a milk production line where every production process step matters for your health and satisfaction.

Milk production has three main stages: milking and collection, processing, and packaging with distribution.

Modern farms use technology and strict hygiene to keep milk safe and monitor cow health.

Processing steps like pasteurization and homogenization kill harmful bacteria and improve milk quality.

Packaging and delivery use careful controls to keep milk fresh and safe until it reaches your home.

Every step in milk production works together to provide you with nutritious, high-quality milk you can trust.

You start the journey of milk right on the dairy farm. Modern farms use advanced technology to make the production process efficient and safe. Robotic milking systems now handle much of the work. These machines let cows enter the milking area when they choose. Robotic milkers attach vacuum cups to each teat, drawing milk through stainless steel pipes. The system collects data about each cow’s health and milk yield. Farmers use this information to improve herd management and milk quality.

You also see cow monitors and rumination collars on many farms. These devices track cow activity and health, helping farmers spot problems early. Automatic calf feeders ensure young animals get the right nutrition.

Hygiene is critical in the production process. You wear rubber gloves and use sanitized equipment. Before milking, you clean and disinfect the cow’s teats. After milking, you apply a disinfectant dip to protect against bacteria. You keep the milking area and equipment spotless to prevent contamination. Sick cows stay out of the milking line to protect the milk supply.

Once collected, milk flows into bulk storage tanks made of stainless steel. These tanks cool milk rapidly to about 4°C (39°F). Quick cooling is vital in the production process because it stops bacteria from growing. You keep the milk at this temperature until it leaves the farm.

Industry standards say you must store raw milk for no more than 76 hours before processing. The table below shows key requirements for safe storage:

Aspect |

Requirement |

|---|---|

Maximum Storage Duration |

No more than 76 hours from first milking to pickup or processing |

Cooling Temperature |

Cool to 40°F or below within two hours after milking |

Storage Temperature in Bulk Tanks |

Maintain at 45°F or lower until processing begins |

You load the cooled milk into refrigerated tankers for transport to the processing plant. These tankers use stainless steel interiors and airtight seals to keep milk safe and fresh. The refrigeration system keeps milk at about 4°C during the trip.

Before the milk enters the processing plant, it goes through several safety tests. You check for bacteria, temperature, and possible adulteration. Tests also measure fat, protein, and other components to meet quality standards. These steps in the production process ensure that the milk you drink is safe and high quality.

If you ever wondered how is milk made, this first stage shows the care and technology involved before milk even reaches the next step.

When you follow milk from the farm to your table, you see how the milk production line uses advanced technology and strict quality control at every step. The production process in a modern facility includes pasteurisation, homogenisation, and separation & standardisation. Each step ensures that the milk you drink is safe, consistent, and high quality.

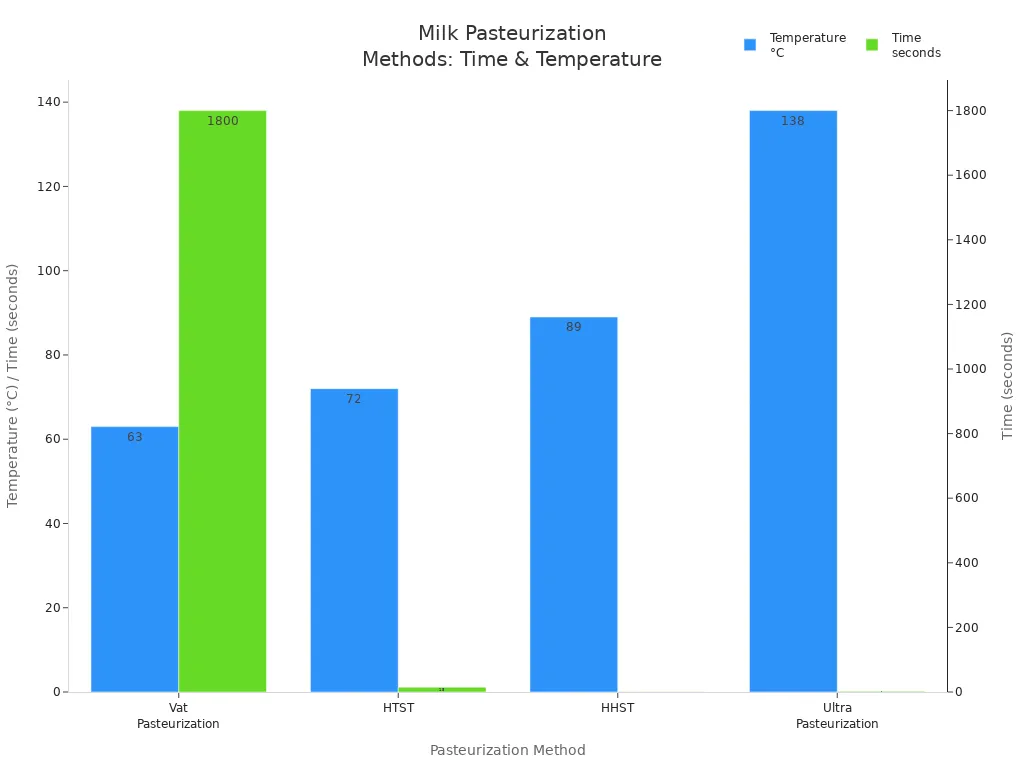

You start with pasteurisation, a critical step in the milk production line. The pasteurisation process heats milk to a specific temperature for a set time to kill harmful bacteria. Raw milk can contain dangerous germs like Listeria, E. coli, and Salmonella. These pathogens are invisible, and you cannot always detect them through testing. Pasteurisation protects you from foodborne illnesses by destroying these bacteria without changing the taste or nutrition of milk.

Most milk processing plants use the High Temperature Short Time (HTST) method. In this method, you heat milk to 72°C (161°F) for at least 15 seconds, then cool it quickly. This process keeps milk fresh and safe for you and your family. Some plants use other methods, such as Low Temperature Long Time (LTLT) or Ultra Heat Treatment (UHT), depending on the product.

Pasteurization Type |

Temperature (°C) |

Time Duration |

|---|---|---|

Low Temperature Long Time (LTLT) |

63 |

30 minutes |

High Temperature Short Time (HTST) |

72 |

15 seconds |

Higher Heat Shorter Time (HHST) |

89 - 100 |

0.01 to 1.0 seconds |

Ultra Heat Treatment (UHT) |

135 |

2 to 5 seconds |

Note: Pasteurisation is essential for milk safety. It reduces the risk of illness, especially for children, seniors, pregnant women, and people with weak immune systems.

After pasteurisation, you move to homogenisation. This step changes the texture and appearance of milk. In raw milk, fat globules rise to the top and form a cream layer. Homogenisation breaks down these fat globules using high-pressure machines. The process pushes milk through fine nozzles at high speed, making the fat particles smaller and evenly distributed.

You notice that homogenised milk looks whiter and smoother. The texture becomes consistent, and you do not see cream separating at the top. Homogenisation also extends the shelf life of milk, keeping it fresh for up to 11 days. The process does not change the flavor or nutrition, but it makes milk more convenient for you.

Aspect |

Effect of Homogenization |

|---|---|

Texture |

Fat globules are broken down and evenly distributed, preventing cream separation and resulting in a smooth, consistent texture. |

Shelf Life |

Smaller fat globules stabilize milk, reducing clumping and spoilage, which extends shelf life. |

Appearance |

Milk appears whiter and more visually appealing due to uniform fat distribution. |

Convenience |

No need to shake milk before use as cream does not separate. |

Large-scale milk processing plants use pressure homogenisers for this step. These machines use high-pressure technology and advanced controls to ensure every batch meets strict standards. You benefit from a production process that uses real-time monitoring and automation to keep milk quality high.

The next step in the milk production line is separation and standardisation. Here, you use centrifugal separators to spin milk at high speed. This process separates cream from skim milk. You can then adjust the fat content to create different types of milk, such as whole, 2%, 1%, or skim milk.

Standardisation means you blend cream and skim milk in exact amounts. This ensures every carton of milk has the same fat content and nutrition, no matter where the milk comes from. You also add back vitamins A and D, which are removed with the cream, to meet nutritional standards.

The production process uses precise instruments and continuous monitoring. You check fat, protein, and solids content to guarantee consistency. This step allows you to enjoy milk with reliable taste and nutrition every time.

Tip: Standardisation helps you get the milk you prefer, whether you choose whole milk for richness or skim milk for lower fat.

Here’s how the standardisation process works:

You measure the fat content of raw milk.

You calculate how much cream to remove or add using the Pearson square method.

You blend cream and skim milk to reach the target fat percentage.

You verify the final product with quality control tests.

The milk production line relies on advanced technology and strict quality control at every stage. Automated systems, real-time data, and skilled workers ensure that the production process delivers safe, high-quality milk to you. When you ask, "how is milk made," you see that each step in milk processing protects your health and guarantees the best product.

After processing, you see how the journey of milk continues through careful packaging and distribution. Each step protects the freshness and safety of fresh milk until it reaches your table.

You watch as automated bottling systems fill and seal each container with precision. These machines use stainless steel parts that touch only the milk, keeping everything hygienic. Before filling, specialized cleaning machines wash and sterilize every bottle. This process removes bacteria and ensures that only safe, fresh milk enters the packaging. The bottling line uses nitrogen flushing or vacuum sealing to reduce oxygen inside the package. This step helps prevent bacterial growth and keeps milk fresh longer. Automated controls monitor every stage, so you can trust the safety and quality of each bottle.

Packaging Material |

Characteristics & Impact on Milk Shelf Life |

|---|---|

Glass bottles |

Non-permeable, non-reactive; heavy and fragile; good barrier to oxygen and contamination. |

Plastic bottles (PE, PET) |

Lightweight, shatter-resistant; pigmented PET blocks light and reduces oxidation; some risk of chemical leaching. |

Cartons (paperboard + PE + Al) |

Eco-friendly; effective light barrier; commonly used for milk packaging. |

UHT packaging (aseptic multilayer) |

Enables extended shelf life (3 months to 1 year) without refrigeration; protects milk from contamination and oxidation. |

Tip: The choice of packaging material affects how long your fresh milk stays safe and tasty. UHT packaging can keep milk shelf-stable for months.

You notice that every milk package carries important information. Labels must show the product name, net quantity, ingredients, manufacturer’s address, country of origin, and allergen warnings. All details appear clearly in English, using readable fonts and layouts. This helps you make safe and informed choices.

Before milk leaves the plant, you see strict quality control checks. Technicians test for bacteria, fat, protein, and taste. They inspect packaging for leaks, check code dates, and verify seals. Sensory panels taste and smell the milk to catch any defects. These steps ensure that only high-quality, safe milk reaches you.

Required label information:

Product name

Net quantity

Ingredient list

Manufacturer’s address

Country of origin

Allergen warning (milk)

Clear, readable format

You rely on a cold chain to keep milk fresh during delivery. Refrigerated trucks transport milk at temperatures below 4°C (40°F). Drivers load milk at the right temperature and use pre-cooled containers. Temperature monitors track milk throughout the journey. If a problem occurs, tracking systems alert the team to fix it quickly.

Key steps for safe delivery:

Use refrigerated trucks and pre-cooled containers

Load milk away from truck walls for airflow

Monitor temperature with data loggers

Maintain strict cleaning schedules for vehicles

Note: The entire trip from plant to store usually takes less than two days. This speed, along with temperature control, keeps your fresh milk safe and delicious.

You see how the three main stages—milking and collection, processing, and packaging—work together to deliver safe, high-quality milk. Each step protects you from contamination and ensures that the milk you drink meets strict standards.

Careful management on the farm prevents drug residues and low-quality milk from entering the supply.

Processing uses advanced equipment and hygiene practices to keep milk safe and nutritious.

Distribution brings milk to you fresh, thanks to strong quality control and supply chain management.

Science-based safety systems, like HACCP, and good agricultural practices reduce risks at every stage. Modern dairy farms use technology and health monitoring to improve consistency and animal welfare. You benefit from reliable milk production that meets your needs for nutrition and safety.

You can trust that the milk on your table comes from a system designed for your health and peace of mind.

A milk production line is a series of automated steps that collect, process, and package milk. You see machines handle milking, pasteurization, homogenization, and bottling. This system keeps milk safe and fresh for you.

You watch liquid milk enter the milk powder production line. Machines evaporate water, then spray-dry the milk into powder. This process creates shelf-stable milk powder for easy storage and transport.

A milk processing line focuses on treating raw milk—pasteurizing, homogenizing, and standardizing it. The milk production line includes these steps plus milking, collection, packaging, and delivery. You get safe milk from both systems.

You can adapt a milk production line for almond milk production. The almond milk production line blends almonds with water, filters the mixture, then processes and packages it like dairy milk. You get fresh almond milk with similar safety standards.

Quality control checks every step in the milk production line. You see tests for bacteria, fat, and taste. These checks protect you from contamination and guarantee safe, high-quality milk or milk powder every time.